Recently, the environmental protection department implemented: "Do a good job in the connection of environmental impact assessment and pollution permit system"

Among them, the problem of industrial wastewater discharge is mentioned. The industrial production process needs to consume a lot of raw materials and energy, and while obtaining the required products, it also brings a lot of pollutants. Industrial products are diverse, and the industrial wastes produced are not the same. Industrial wastes can be divided into solid wastes, liquid wastes and gas wastes according to their forms, collectively referred to as the "three wastes", and different forms of waste have different treatment methods.

So how to choose a good treatment method?

low cost

Zero discharge treatment plan for metal processing waste liquid.

Ningbo Shengfeng Electromechanical specializes in processing industrial fluid purification, and is the first to realize zero waste liquid discharge in the whole process of metal processing.

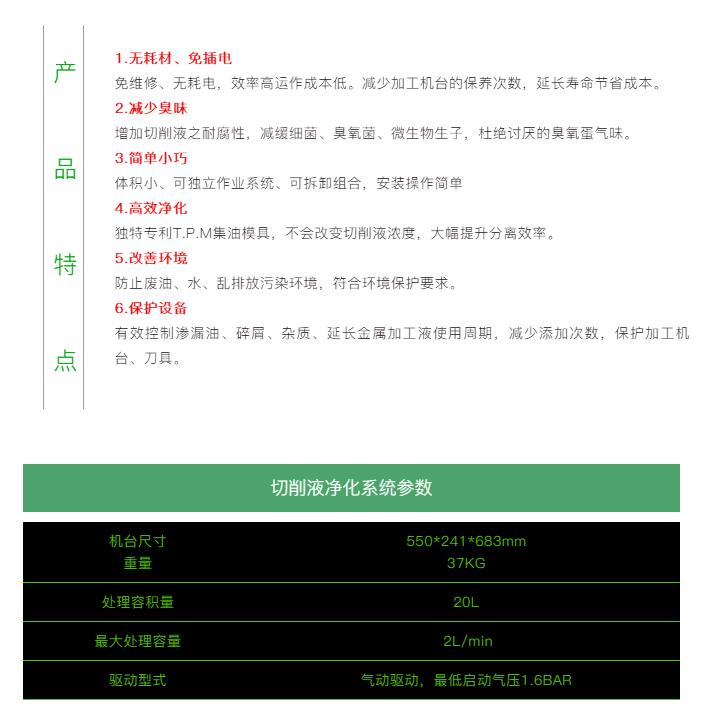

WH-20

Cutting fluid purification system

What are the benefits for manufacturers?

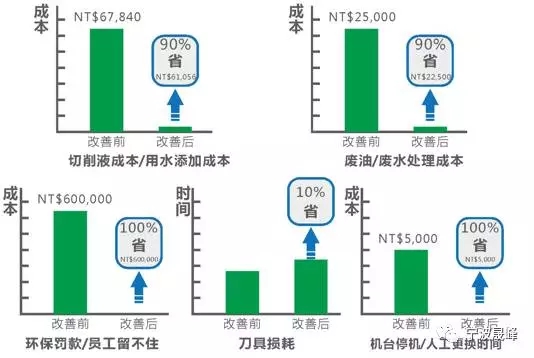

The value brought by the cutting fluid purification system

Reduce the cost of in-plant expenditure

Save energy and reduce carbon

Improve the factory environment

Improve production capacity

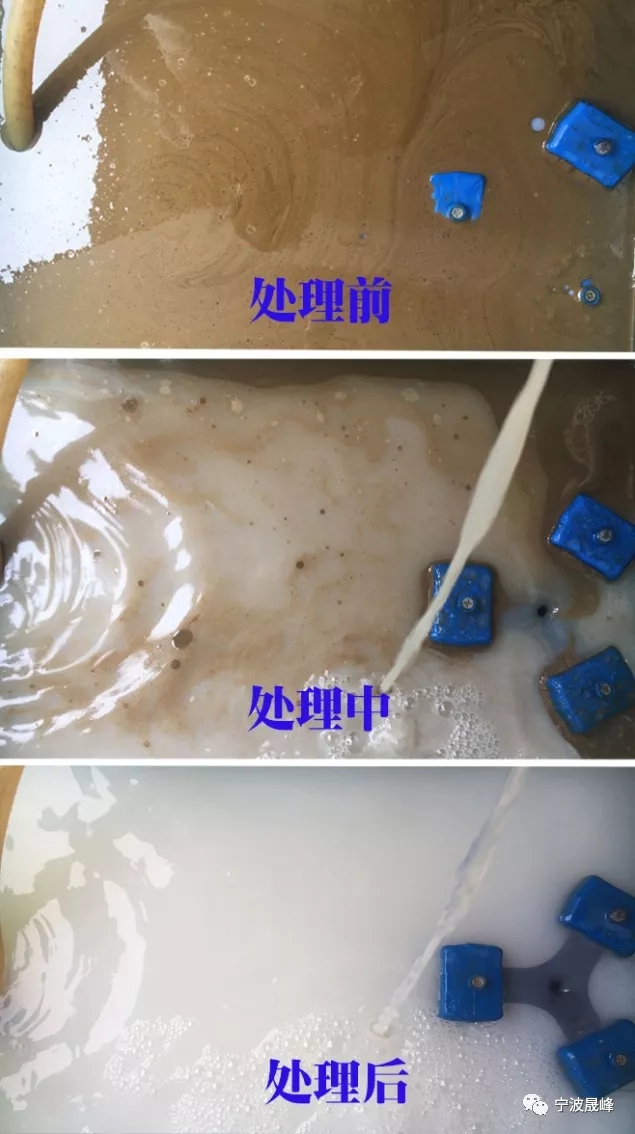

Effect observation

Comparison chart of cutting fluid purification system before and after treatment

Effect demonstration

Cutting fluid purification system---video demonstration

![]() mxwhcg@foxmail.com

mxwhcg@foxmail.com![]() mxwhcg@foxmail.com

mxwhcg@foxmail.com