Welcome to Ningbo Shengfeng Environmental Protection Equipment Co., Ltd. | Focus on machining filtration solution service provider

Sales Hotline: 188 8866 5866 ![]() mxwhcg@foxmail.com

mxwhcg@foxmail.com

Welcome to Ningbo Shengfeng Environmental Protection Equipment Co., Ltd. | Focus on machining filtration solution service provider

Sales Hotline: 188 8866 5866 ![]() mxwhcg@foxmail.com

mxwhcg@foxmail.com

Cutting fluid (cutting fluid, coolant) is an industrial liquid used in the metal cutting and grinding process to cool and lubricate tools and processed parts. The cutting fluid is scientifically compounded by a variety of super-functional additives. It has good cooling performance, lubrication performance, anti-rust performance, oil removal cleaning function, anti-corrosion function, and easy dilution characteristics at the same time. It overcomes the problems of traditional soap-based emulsions that are easy to smell in summer, difficult to dilute in winter, and have poor anti-rust effect. It has no adverse effect on lathe paint. It is suitable for cutting and grinding of ferrous metals and is currently the most advanced grinding product. All indexes of cutting fluid are better than saponified oil. It has the characteristics of good cooling, cleaning and rust prevention, and it is non-toxic, odorless, non-corrosive to human body, non-corrosive to equipment, and non-polluting to the environment.

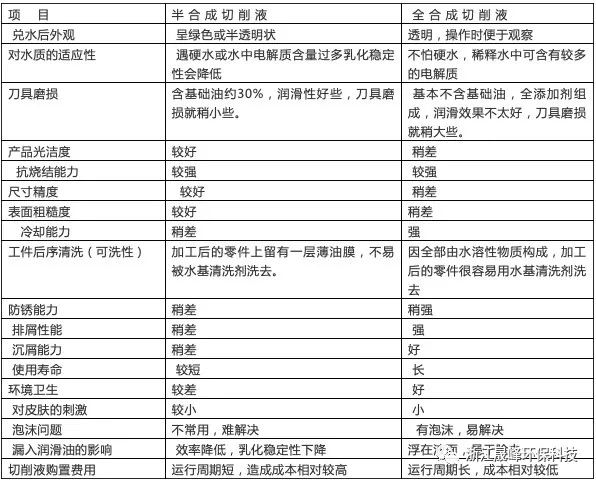

Water-based cutting fluids can be divided into emulsions, semi-synthetic cutting fluids and fully synthetic cutting fluids. The classification of emulsion, semi-synthetic and fully synthetic usually depends on the type of base oil in the product: emulsion is a water-soluble cutting fluid that only uses mineral oil as the base oil; semi-synthetic cutting fluid contains both mineral oil and chemical synthesis basis Oil-based water-soluble cutting fluids; fully synthetic cutting fluids are water-soluble cutting fluids that use only chemically synthesized base oils (that is, without mineral oil). Each type of cutting fluid contains various additives besides base oil: anti-rust agent, non-ferrous metal corrosion passivator, defoamer, etc.

However, as the cutting fluid is recycled, it will gradually deteriorate and even become odorous, which will become waste fluid. The disposal of waste fluid is a headache. Therefore, the daily maintenance of the cutting fluid is related to its service life. This can greatly reduce the cost of the enterprise. This article sorts out the main points of deterioration of cutting fluid, including its daily maintenance.

Cutting fluid that has deteriorated and cannot be used

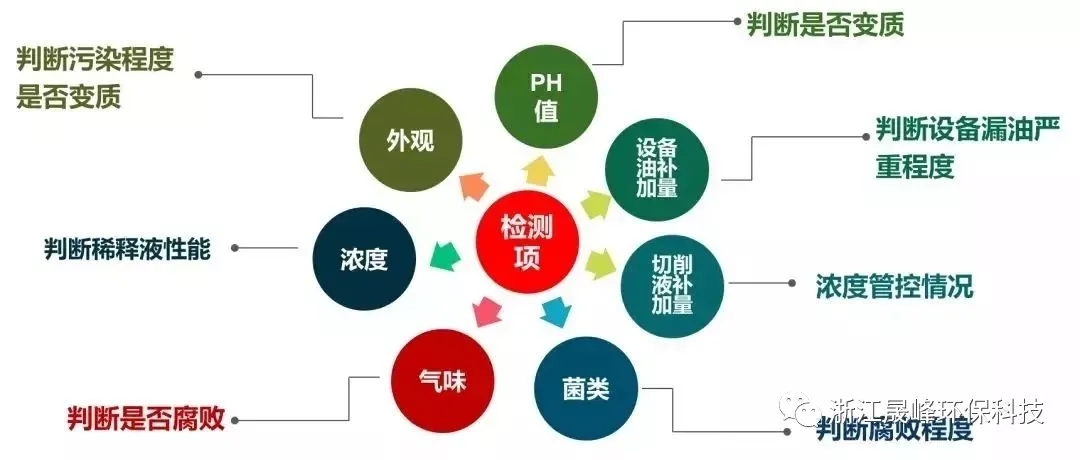

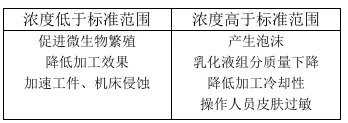

1. Concentration Management The standard of synthetic cutting fluid is duGB/T6144, and the detection concentration is generally 5%. The dilution concentration of most cutting fluids is also 5%. The cutting fluid in the market is generally 3%-10%, depending on the details. Product performance and processing load are determined.

Precautions:

1. At any time, use advanced mixing devices to mix and configure processing fluids as much as possible;

2. Concentrate must be injected into the water during manual mixing;

3. If you want to increase the concentration of the processing fluid, it is recommended to directly add the concentrated fluid at the appropriate mixing point in the reservoir;

4. Thoroughly mix the processing fluid before measuring the concentration;

5. Use refractometer and chemical titration to test the concentration of the processing fluid;

6. If the method of configuring cutting fluid is correct at the beginning, good results will be obtained.

The detection methods of cutting fluid concentration include: refraction method, acid hydrolysis demulsification method, chemical titration method and instrumental analysis method. One of the simplest and most effective is the refractometer, which requires only a small amount of working liquid to be dropped on the panel of the refractometer, and the refractometer can be read out by aiming the refractometer at the bright light. The refractive index multiplied by the product's unique refractive index is the concentration of the working fluid. Sometimes the dividing line of the readings is not clear due to the mixing of miscellaneous oils, and you need to estimate the readings at this time.

Refractometer

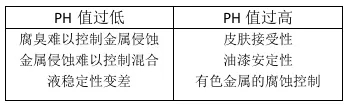

2. PH value detection

Normal cutting fluid PH standard range is 8.5-9.5.

Reasons for the increase in PH value: solution is mixed in the equipment system;

Reasons for the drop in PH value: the growth of bacteria → the equipment workpieces are rusted, produce unpleasant odors, and the performance of the emulsion is unstable.

For the oil that is mixed with the system solution and causes the PH to rise, filter equipment can be used to effectively remove solid and oil impurities, such as professional oil skimmers, coalescing filters, oil skimmers, and centrifuges.

The drop in pH caused by the growth of bacteria is what we will discuss next.

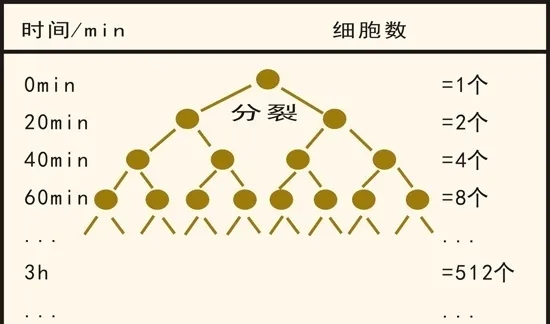

3. Bacteria breeding problem Cutting fluid is a natural breeding place for microorganisms. The two main categories are aerobic bacteria and anaerobic bacteria. Bacteria multiply, the organic acid and salt produced cause corrosion, and make the performance of the lubricating fluid drop, and even decay and deteriorate to meet the production.

细菌大量滋生的切削液

The powerful reproduction speed of bacteria

Precautions:

1. When the ph value of the cutting fluid is between 8.3 and 9.2, it is difficult for du bacteria to survive, so new cutting fluid should be added in time to increase the ph value.

2. Keep the cutting fluid clean, and don't let the cutting fluid come into contact with dirt, oil, food, tobacco, etc.

3. Frequent use of fungicides.

4. Keep the workshop and machine tools clean.

5. If the equipment does not have a filtering device, the oil slick should be skimmed off regularly to remove the dirt.

6. Use cutting fluid of high quality and good stability.

7. Using pure water to prepare a concentrated solution is not only easy to prepare, but also can improve the lubricity of the cutting fluid, reduce the amount of chips carried away, and prevent bacterial erosion.

8. When using, it is necessary to control the ratio of concentrated liquid in the cutting fluid not to be too low, otherwise it is easy to cause bacteria to grow.

9. Since the oil used by the machine tool contains bacteria, it is necessary to minimize the oil leaked from the machine tool into the cutting fluid.

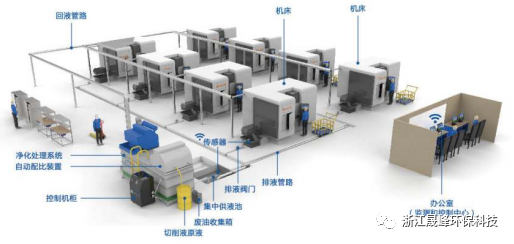

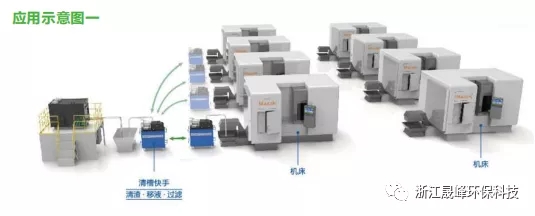

Method 1: Centralized liquid supply system, automatic processing of the entire system for refilling, returning liquid, removing chips, and purifying;

Method 2: Centralize the treatment system, purify and regenerate the waste liquid, and re-add it to the machine tool for recycling;

Method 3: Stand-alone system, fixed next to the machine tool to keep the water tank in a clean state;

Four. Water quality configuration Ideal water hardness for liquid preparation: 80~125ppm, soft water <100ppm, hard water>200ppm The mineral content of the solution will increase due to the evaporation of water and the replenishment of new liquid. After a period of time, the chloride and sulfate will accumulate and gradually become hard water. Treatment and preparation of water: filtration, softening, demineralization, bacterial purification; Water standard: deionized, PH=7 neutral; Detection object: river water, well water; It is necessary to treat the used water first to eliminate the contamination of the cutting fluid by microorganisms in the water; Scientific ratio can prolong the service life of cutting fluid; The cutting fluid made of soft water will bubble. Can be adjusted with calcium acetate; Cutting fluid made of hard water: lead to poor stability. Dirt in the centralized liquid supply pool, central system filter, and liquid tank; Too high chloride will cause corrosion and rancidity; Too much sulphate will cause rancidity; V. Standard cleaning method of machining center 1. Machine tool cleaning agent→1%~2%, disinfectant 200PPM. Turn on the coolant circulation pump, all machine tool coolant valves, the maximum flow rate of continuous cycle flushing for 4 hours; 2. Check the tanks, pipes, and chip conveyors of the machine tool, and clean up the remaining iron chips and deposited sludge in these parts; 3. Stop the circulation, draw out the waste liquid, and thoroughly remove the sludge at the bottom of the tank; 4. Add water to the liquid tank to ensure the lowest circulating liquid level, start the cycle for half an hour, and rinse the liquid supply system pipeline; 5. Stop the circulation, draw out the rinsing liquid, and clean up the sludge at the bottom of the tank; 6. Inject clean water, the water volume is about 70% of the volume; 7. Recirculate and stir while slowly adding the prepared solution, according to the normal working tank volume, configure it into a standard concentration of working solution 8. Cycle time> 2h, check the liquid concentration, the machine tool with serious oil pollution needs 3 to 4 cycles to clean.

Follow the official public account

Copyright ©2016- 2025 Ningbo Shengfeng Environmental Protection Equipment Co., Ltd. All Rights Reserved.

POWER: RSWL