Welcome to Ningbo Shengfeng Environmental Protection Equipment Co., Ltd. | Focus on machining filtration solution service provider

Sales Hotline: 188 8866 5866 ![]() mxwhcg@foxmail.com

mxwhcg@foxmail.com

Welcome to Ningbo Shengfeng Environmental Protection Equipment Co., Ltd. | Focus on machining filtration solution service provider

Sales Hotline: 188 8866 5866 ![]() mxwhcg@foxmail.com

mxwhcg@foxmail.com

Ningbo Shengfeng Environmental Protection Equipment was established in 2014 and is located in Zhenhai District, Ningbo City. It is a company integrating R&D, production and sales.

Have a highly dedicated, technologically advanced and experienced technical team dedicated to helping manufacturing companies solve the high cost of metalworking liquid waste treatment

Improve product quality and grade through independent innovation and cooperation; provide customers with safe and reliable solutions through considerate technical services

The company has established long-term and stable cooperative relations with many retailers and agents.

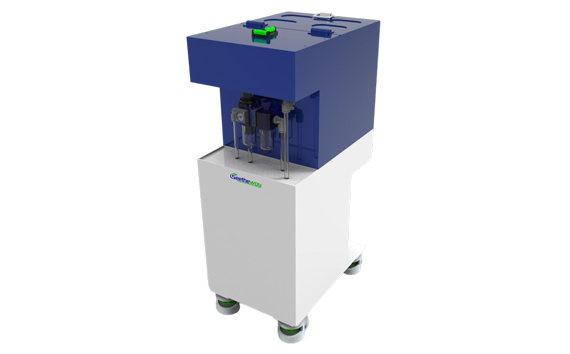

1. Fast oil removal, oil removal rate up to 98%

2. Double sterilization ozone, greatly extending the life cycle of cutting fluid, saving the cost of hazardous waste treatment

3. Fully intelligent PLC control system, easy to operate and improve work efficiency

4. Movable filter, does not affect the normal work of the machine

5. Pure physical filtration, does not affect the PH value, concentration and composition of the cutting fluid

6. Without any consumables, reducing unnecessary maintenance costs in the later period

Compact structure, easy to move, easy to operate, fast suction

Reduce cost, improve environment, improve cleaning efficiency

The double economic benefits of retaining the active ingredient for reuse, concentration and emission reduction

Common problems with liquid dispensing:

1. The specific dosage per unit of time cannot be measured, which cannot provide accurate judgment basis for the yield rate.

2. Liquid movement through manual, low efficiency, the movement process is easy to cause waste and environmental pollution.

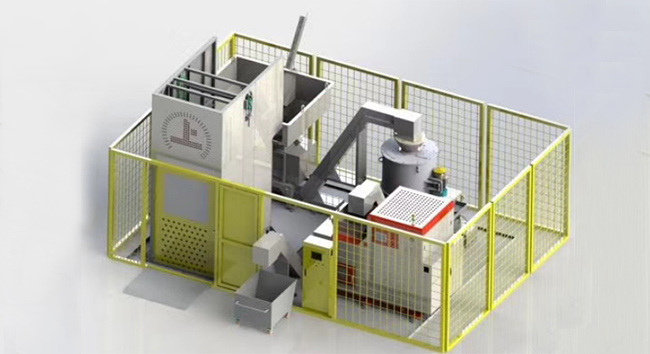

This equipment adopts the centrifugal filtration, high efficiency and long life of filters, with special turbines, and than on the market with low energy consumption, air volume of oil mist collector filtration material after a long validation, compatibility through pressure test, super convenient maintenance, appearance also have creative design, make workshop look more concise as a whole.

Is mainly used for all kinds of hydraulic servo system, power equipment, chemical industry, transformer industry, military industrial enterprises and other kinds of hydraulic and lubrication oil in the system, including the hydraulic oil in water emulsion, emulsion breaking filter oil machine can remove the impurities in oil, moisture, prevent oil oxidation and acidity rise, keep oil lubrication performance, prolong the life of oil and equipment used, reduce the enterprise cost, Ensure continuous operation of equipment without fault.

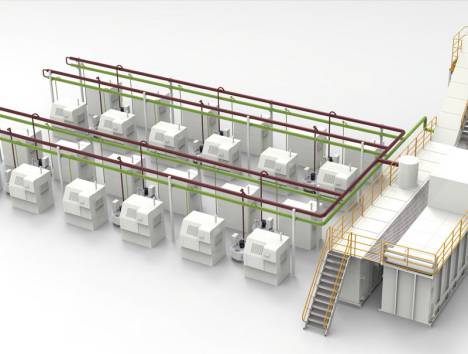

The concentrated filtration of cutting fluid can be used for cutting chips in the liquid. It is suitable for processing conditions such as emulsions, water-based synthetic fluids and low-viscosity cutting oils. It can improve the processing accuracy of the workpiece and prolong the service life of the cutting fluid. The filtering system is composed of a scraper. Conveyor, scraper filter, degreasing unit, aeration unit, liquid distribution unit, emptying circulation pump, liquid supply pump set, electronic control system and other parts. For precision grinding conditions, pre-coating unit and refrigeration unit can be selected to enable the filtration system to achieve higher filtration accuracy and temperature required by the process.

1. The floor area is reduced and the space utilization rate is improved.

2. Reduce dumping times and improve production efficiency.

3. Reduce equipment failures caused by metal shavings.

4. Improve the ground slippery, reduce the possibility of industrial accidents.

5. Build a green and healthy enterprise and establish a good social image.

6. Reduce waste emissions, improve the earth and human living environment to make contributions.

Follow the official public account

Copyright ©2016- 2025 Ningbo Shengfeng Environmental Protection Equipment Co., Ltd. All Rights Reserved.

POWER: RSWL