Welcome to Zhejiang Shengfeng Environmental Protection Technology Co., Ltd. | Focus on machining filtration solution service provider

Sales Hotline: 188 8866 5866 ![]() mxwhcg@foxmail.com

mxwhcg@foxmail.com

Welcome to Zhejiang Shengfeng Environmental Protection Technology Co., Ltd. | Focus on machining filtration solution service provider

Sales Hotline: 188 8866 5866 ![]() mxwhcg@foxmail.com

mxwhcg@foxmail.com

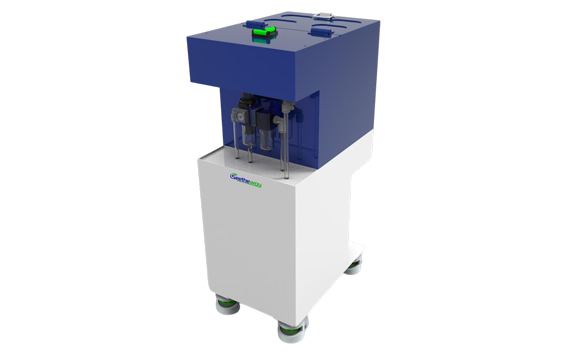

Shengfeng Environmental Protection Technology LF-X15 cutting fluid purification equipment, through unique green, patented technology, in a purely physical way, effectively removes fine particles, removes oil, controls microorganisms, and prolongs the life of cutting fluid.

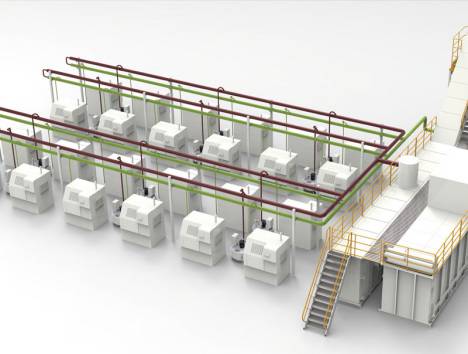

The scraper filter system is widely used for centralized filtration of cutting fluid, which can improve the machining accuracy of the workpiece and prolong the service life of the cutting fluid.

Frequently Asked Questions about Dosing: 1. The specific dosage per unit time cannot be measured, and an accurate basis for judging the yield cannot be provided. ...

Shengfeng Environmental Protection Technology LF-B15 cutting fluid purification equipment, through unique green, patented technology, in a purely physical way, effectively removes fine particles, removes oil, controls microorganisms, and prolongs the life of cutting fluid.

The filter material of the ultra-micro equipment is made of high temperature sintering by recrystallization technology. Its porous support layer, transition layer and protective layer are all special composite materials, and its filtration precision is microfiltration and ultrafiltration. The ultra-fine filtration system is a fluid separation process in the form of "cross-flow filtration". The raw material liquid flows at a high speed in the tube, and the clear permeate containing small molecular components is driven by the pressure to pass through the dense layer of the material in the vertical direction. The turbid concentrate containing macromolecular components is retained, so as to achieve the purpose of clarifying, separating, concentrating and purifying the fluid.

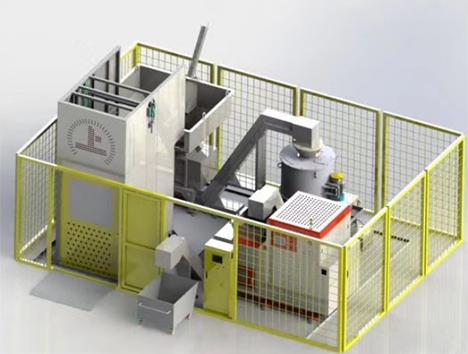

Metal press is mainly used in the recovery and processing industry and metal smelting industry. Metal chip pressing function will be all kinds of metal chips (iron chips, copper chips, aluminum chips, titanium, etc.) extrusion molding, automatic operation from lifting and turning - crushing - transport deoiling - transport - automatic pressing block - automatic block, one key forming. More modules for you to choose, for you to customize the exclusive scrap pressing system.

This equipment adopts the centrifugal filtration, high efficiency and long life of filters, with special turbines, and than on the market with low energy consumption, air volume of oil mist collector filtration material after a long validation, compatibility through pressure test, super convenient maintenance, appearance also have creative design, make workshop look more concise as a whole.

High precision oil filter is a comprehensive processor, with strong off-line processing ability, can effectively deal with various indicators in the contaminated oil, maintain the cleanliness of the oil in use. Targeted to solve the pollution, emulsification and other problems encountered in the use of oil, improve the service life of oil, to solve all the pipeline filter can not deal with fine impurities, part of the water and a small amount of oxides. Let the waste oil regenerate.

The vortex vacuum pump uses compressed air as the power source, without electricity. This product has strong conveying and cleaning capacity for oil and oil-water mixture and other liquids, and is mainly used for liquid conveying. The operation of the vortex pump is simple. Just turn the nut at the top to change the discharge and suction state. Vortex vacuum pump is used to replace the oil, water, coolant, lubricating oil and other liquids in the equipment. In line with national environmental standards, it is an excellent liquid conveying and cleaning tool in the production process of modern enterprises.

1, the installation operation is simple, one key start; Large flow fast ratio; The system automatically enters the standby state, and the ratio is accurate and stable, effectively extending the service life of cutting fluid and machining tools

2, high degree of automation, only need to set once, no frequent operation

3, cost-effective, professional team design, research and development, production, master the core technology, workshop pipe liquid supply can be free design installation scheme according to the customer site situation, in order to achieve better use experience.

4, the ratio ratio and use concentration can be adjusted at any time in the control panel, to provide you with more comprehensive services and more options for use

5, the power supply uses 220V common voltage, do not need to worry about the choice of electricity, efficient, simple, convenient, plug can be used

6, prepare the appearance of the processing process is delicate, the galvanized sheet and stainless steel square tube reinforced surface using paint processing, practical, beautiful, durable

7, the equipment size is compact, style, style customers can choose the appropriate size and use mode according to the actual situation

8, 3.6 million caster, easy to move, labor saving, simple and convenient

Series of problems faced in the use of cutting fluid:

Cutting fluid is a consumable, and there is a cost for using the field, and there is a cost for liquid waste disposal. It is 2500~8000 yuan/ton for hazardous liquid waste disposal.

Poor use and management of cutting fluid, affecting the precision of processed products

Improper use of cutting fluid will affect tool life, increase cost, tool replacement, affect the rate of machine tool operation

Environmental pressure is increasing, improper disposal of waste cutting fluid, there is a huge environmental risk

Occupational health risks during application of cutting fluid

Using the specific gravity difference between solid particles and liquid, under the action of centrifugal force, solid-liquid separation effect is achieved

Follow the official public account

Copyright ©2016- 2021 Zhejiang Shengfeng Environmental Protection Technology Co., Ltd. All Rights Reserved.

POWER: RSWL